How print on demand works and why it somtimes fails.

Date

Category

Writer

TL;DR

I have built multiple seven-figure brands using traditional print on demand. I have shipped tens of thousands of orders. My products have been worn by WRC drivers and Playboy models alike. But for all that traction, I lost sleep. And more importantly, I lost hundreds of thousands in profit.

What took me over three years to learn, you can understand in five minutes.

This is how print on demand works. And why we rebuilt it from the inside out.

What Most Creators Discover Too Late

Your first sale always feels different. There is a sense of momentum. Proof of concept. A door opening.

Then the product arrives.

No branded mailer. No insert. Just a crumpled polybag with a shirt sealed inside. It smells like vinegar, synthetic. The print feels flat. The fabric is thin, translucent in daylight. The fit is off. The body hangs low. The neckline feels tight. The sleeves stick out. It does not feel like something anyone chose with intention.

And the print, which once looked bold on screen, now looks small and desaturated. The colors fall away. The design has no presence.

This is what most customers experience when they buy from a print on demand brand. It does not feel like a brand. It feels like a shortcut.

They will not come back. Not because they disliked your idea. But because it never showed up in the first place.

That is the real cost of bad product. It is not just a refund. It is a broken promise. And it sets off a chain of problems. Support tickets. Chargebacks. Negative comments. Declining store ratings. Ads that stop converting. Organic reach that disappears. The product becomes a liability.

Even for brands doing over $100k a month, this is where it starts to fall apart. Founders come to us exhausted. The profit is thin. The stress is constant. It becomes a cycle of fixing problems rather than building momentum.

How We Rebuilt Print on Demand

In 2022, we created Airventory.

What began as a private backend for a few select brands is now open to anyone building with care. We did not aim to be the cheapest. We focused on being the best.

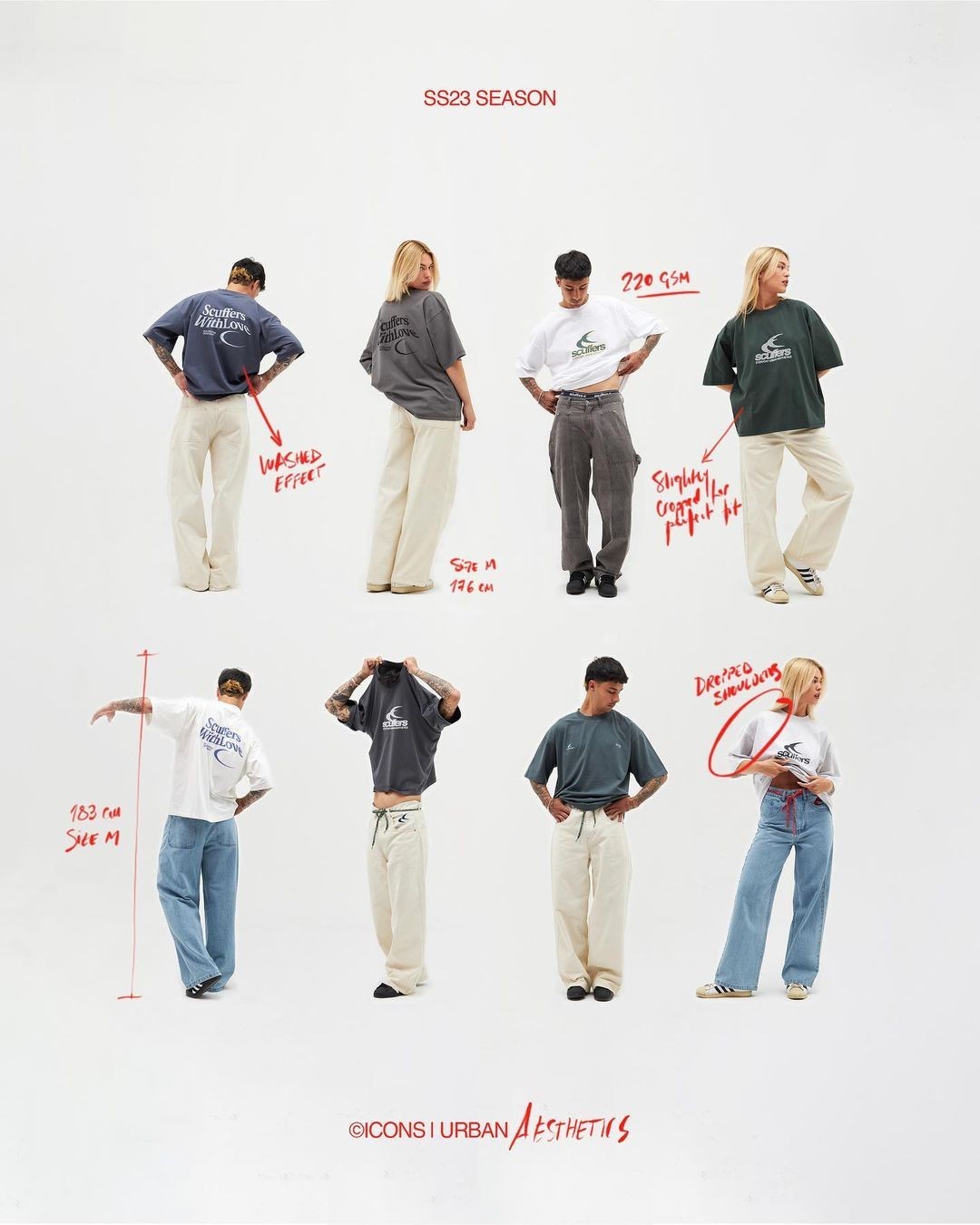

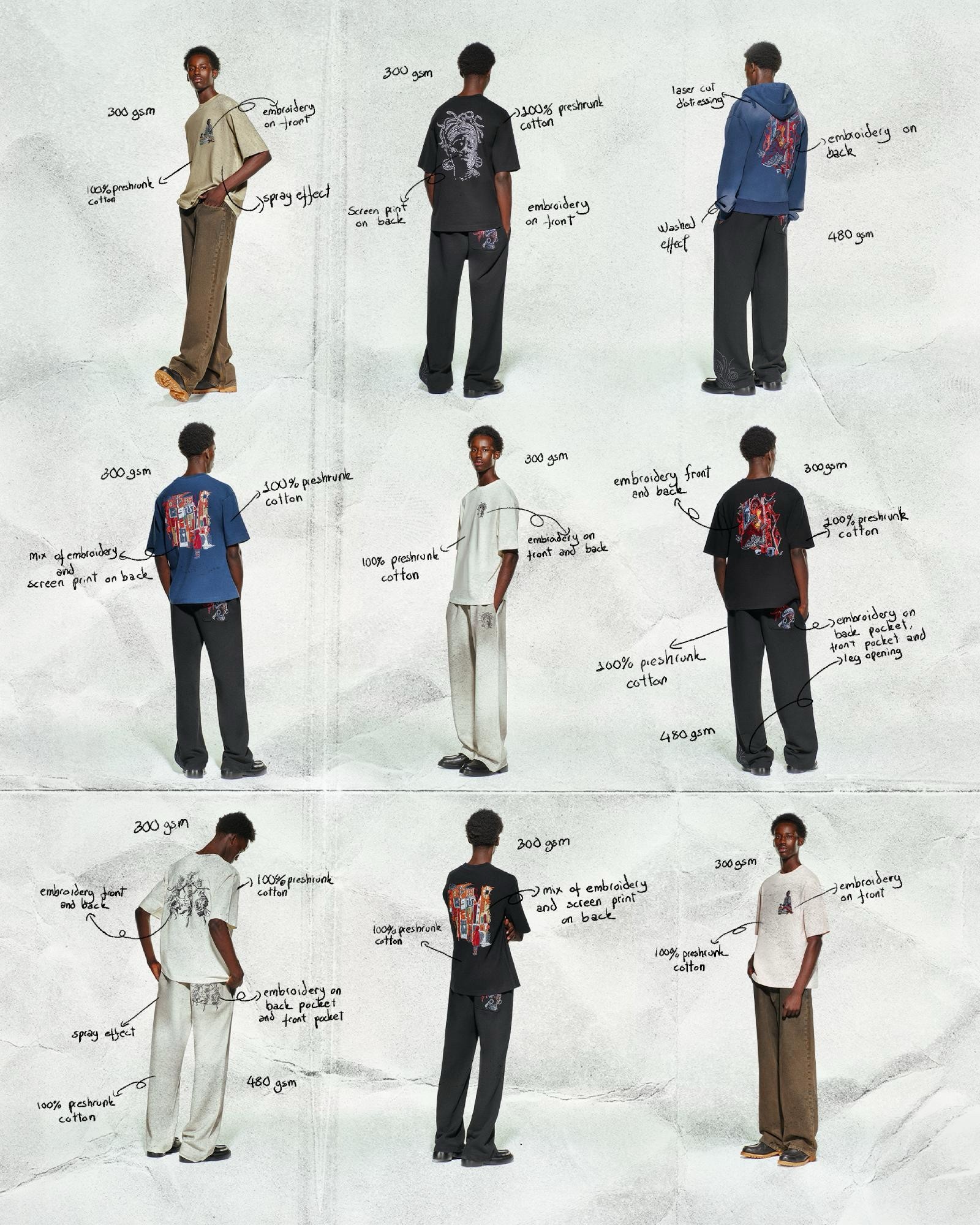

Instead of generic blanks, we reverse-engineered the bestselling fits in fashion. Our R&D team tracks over two hundred fifty million live data points per quarter to identify what sells and why. Our blanks match the weight, composition, and structure of labels doing over one hundred million a year.

You may or may not recognize the blanks. But your customers will feel the difference.

Setup is simple. Upload your design. Publish it to your store. We integrate with Shopify, Etsy, WooCommerce, and more.

From there, we handle everything. Production, finishing, packaging, and shipping. Fully white labeled. Delivered under your brand.

You carry no inventory. You pay only when something sells.

Our print quality leads the Industry. We print at twelve hundred DPI for sharp detail and true color. Our inks are AATCC rated for durability. Our 60x60cm print zones are large enough to support full creative layouts. Our packaging elevates the unboxing experience. Every order feels considered.

This is how your product becomes your advantage. Because the customer notices. And when they do, they return.

The Truth About Bulk Production

Many founders still believe that bulk production is the next step. It looks more official. It feels more serious. But the outcome rarely matches the intent.

Lead times stretch across seasons. Freight and customs erode your margin. You are forced to predict sizing, color, demand, and design. Often with no data. And when stock finally lands, quality is inconsistent. Corrections take time. Rework adds cost. Managing it becomes a full-time job.

This is not just true for small brands. LVMH wrote off over three billion in unsold product last year. Burberry destroyed thirty six million in inventory to protect its image.

If billion dollar teams cannot forecast demand, why should you be expected to?

This is why more founders are replacing bulk entirely with Airventory. What once took six months now takes minutes. You launch faster. You hold no stock. You build with data instead of guessing.

Product Comes First

Every founder has a different approach. But the one principle they all agree on is simple. Product is the No.1 most important aspect of any brand.

It is what drives retention, word of mouth, and repeat purchases. It is what allows a brand to scale without constantly starting over.

A poor product will reveal itself in comments, reviews, and returns. A great product becomes a signal. It keeps customers engaged. It gives your marketing a foundation.

At Airventory, this is our entire focus. The fit, the fabric, the construction, the print. Our blanks are the same weight and structure used by the brands your customers already trust. The ink is vivid. The feel is premium. The packaging reflects the care you put into the brand.

This is not just print on demand. It is a manufacturing system designed for people building something real.

Who This Is For

Airventory is used by independent creators, design studios, and scaled operators. Some just getting started. Others moving past eight figures. What they have in common is intent. They care about what they ship.

If you want to build a brand that earns trust, keeps margins clean, and grows without risk, this is the system. You bring the vision. We bring the engine.

Thoughts, ideas, and perspectives on design, simplicity, and creative process.